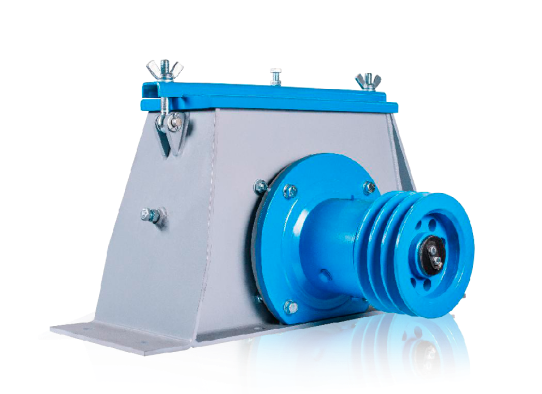

Shot collection and recovery system (elevator, auger) for a shot blaster

Services

-

Technical audit of shot blasting and shot blasting equipment

Technical audit of shot blasting and shot blasting equipment -

Services Overhaul, Modernization of shot blasting and shot blasting equipment

Services Overhaul, Modernization of shot blasting and shot blasting equipment -

Training of staff operating and servicing shot blasting equipment

Training of staff operating and servicing shot blasting equipment -

Covering with protection of the working chamber of the shot blaster

Covering with protection of the working chamber of the shot blaster -

Shot collection and recovery system (elevator, auger) for a shot blaster

Shot collection and recovery system (elevator, auger) for a shot blaster -

Separation system (separator) of shot blasting and shot blasting chambers

Separation system (separator) of shot blasting and shot blasting chambers -

Routine repair and maintenance of shot blasters

Routine repair and maintenance of shot blasters

A shot blaster is a very important piece of equipment in the collection and recovery system of abrasive. It includes: auger, elevator. Many companies underestimate its importance in the operation of the shot blaster and, as a result, our specialists, during the technical audit of shot blasters from customers, in 60% of cases observe catastrophic wear of these assemblies. The auger is designed to move the shot from the working chamber to the elevator or from the elevator to the storage hopper and turbines. The bucket elevator of the shot-thrower is designed to lift the shot to the separation system and the hopper. I.e. in case of wear of the auger, buckets, poor belt tension, or their incorrect design, the amount of shot fed to the turbines decreases (the performance of the entire shotgun decreases).

The main causes of wear: the use of low-quality abrasive, poor separation of shot from sand, dust and waste particles, the use of low-quality spare parts. The auger for the shot blaster can be made of structural or manganese steel, its wear resistance and, as a result, pricing depends on it. Our company is ready to manufacture for you shot-blasting augers of any complexity: from simple to multi-component with several intermediate supports, we can also design and manufacture an auger for your tasks.

As for the bucket elevator, the main reason for the failure of this unit is the use of steel buckets with a wall thickness of less than 2 mm, wear of the tensioner drums, stretching of the belt, the gearbox motor is not correctly selected, or a design error of the manufacturers of shot blasters. Our company can design and develop a bucket elevator for shot blasters of any manufacturers, of any type. On our shot-blasting elevators, we use solid-cast buckets, which, unlike buckets made flexible, have a service life 4 times longer.

Our company can design and manufacture a new recovery system and integrate it into your current equipment, or make local repairs. Stages of work: the customer provides preliminary dimensions of the required assemblies, our specialists make a preliminary calculation of the project cost, then our designer goes to your company and makes measurements of the working chamber, the current augers and the elevator, then a 3-d model with new upgraded assemblies is designed. The next stage is the manufacturing process. The final stage is installation or installation supervision.

The main causes of wear: the use of low-quality abrasive, poor separation of shot from sand, dust and waste particles, the use of low-quality spare parts. The auger for the shot blaster can be made of structural or manganese steel, its wear resistance and, as a result, pricing depends on it. Our company is ready to manufacture for you shot-blasting augers of any complexity: from simple to multi-component with several intermediate supports, we can also design and manufacture an auger for your tasks.

As for the bucket elevator, the main reason for the failure of this unit is the use of steel buckets with a wall thickness of less than 2 mm, wear of the tensioner drums, stretching of the belt, the gearbox motor is not correctly selected, or a design error of the manufacturers of shot blasters. Our company can design and develop a bucket elevator for shot blasters of any manufacturers, of any type. On our shot-blasting elevators, we use solid-cast buckets, which, unlike buckets made flexible, have a service life 4 times longer.

Our company can design and manufacture a new recovery system and integrate it into your current equipment, or make local repairs. Stages of work: the customer provides preliminary dimensions of the required assemblies, our specialists make a preliminary calculation of the project cost, then our designer goes to your company and makes measurements of the working chamber, the current augers and the elevator, then a 3-d model with new upgraded assemblies is designed. The next stage is the manufacturing process. The final stage is installation or installation supervision.

Официальная торговая марка WB Technology

Мы гарантируем сопоставимый срок службы с оригинальными деталями.

Your message has been sent successfully.