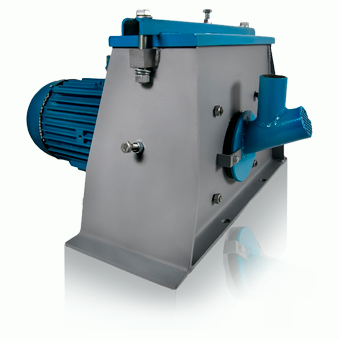

Saturn blast wheel

Turbines

Technical Specifications

The Jupiter shot-blasting turbine can be equipped with an electric motor of 15 - 22 kW

- Turbine rotation speed 2950 rpm

- Turbine throughput 250 kg/min

- The rate of the shot departure 80 m/s

- Turbine wheel diameter 300 mm

- Number of blades 8 pcs

Technical specifications:

Turbine rotation speed - 2950 rpm

Turbine capacity - 250 kg/min

The rate of the shot departure is - 80 m/s

Turbine wheel diameter - 300 mm (double-disc wheel)

Number of blades - 8 pcs

The Saturn turbine can be equipped with an asynchronous electric motor with a power of 11 – 15 kW.

Advantages of our turbine:

Technical specifications:

Turbine rotation speed - 2950 rpm

Turbine capacity - 250 kg/min

The rate of the shot departure is - 80 m/s

Turbine wheel diameter - 300 mm (double-disc wheel)

Number of blades - 8 pcs

The Saturn turbine can be equipped with an asynchronous electric motor with a power of 11 – 15 kW.

Advantages of our turbine:

- High durability of components. We have our own foundry, specialized in the manufacture of spare parts for shot blasters, which allows us to perform components for our turbine according to independently developed chemistry and proven process technology.

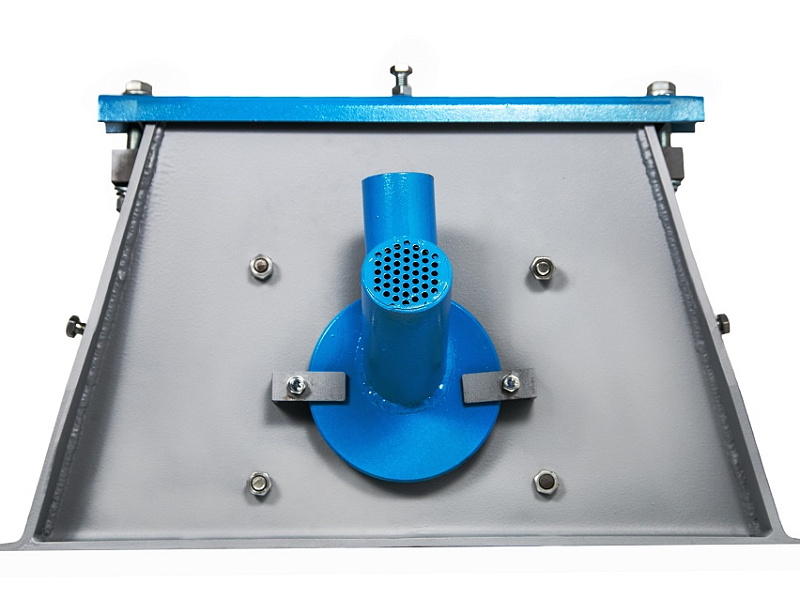

- Maximum performance. The turbine feeder is equipped with a natural air intake system, which allows the shot to be distributed over the entire working surface of the blade and to form the maximum possible width of the shot departure torch.

- Increased protection of moving elements. The design of the armor has additional barriers that prevent the shot from hitting the impeller and hub. Fasteners made of an alloy specially designed for abrasive wear are also used.

- Technical support. The specialists of our company have extensive experience in the operation of shot-blasting equipment and will always be able to help solve the issues of setting up and adjusting shot-blasting turbines and the installation itself.

Your message has been sent successfully.