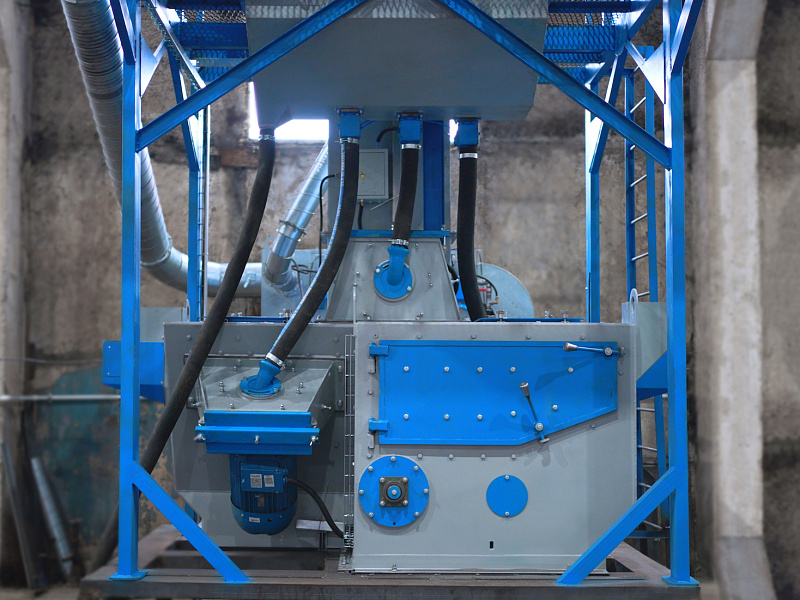

Wire and bar descaling machines

Equipment

Technical Specifications

Characteristics of workpieces

- Maximum part length Not delimited

- Минимальный диаметр обработки 6 mm

- Максимальный диаметр обработки 32 mm

- Максимальная скорость очистки 50 m/hour

- Количество турбин 3 PCS

- Мощность турбин 22 kW

Description

Our company's specialists have designed a shot blaster for cleaning hot-rolled bars with a diameter of 6 - 32 mm, with a cleaning speed of up to 50 m/minute.Working chamber

Unlike our competitors, we do not save on metal. The body of the overhead type shot blaster is made of sheets with a thickness of 8-10mm. The inner walls of the chamber are protected by sheets of chrome-plated cast iron with locks 15 mm thick (hardness 58-62 Hrc).Jupiter shot-blasting turbine

The bar shot blaster is equipped with 3 Jupiter turbines with asynchronous electric motors with a power of 22.0 kW.Elevator

Provides lifting of the contaminated shot abrasive to the separator. The belt tension occurs by moving the upper drum. The conveyor belt is made of abrasion-resistant rubber with a textile gasket. The buckets are solid cast from chrome-plated cast iron. Rotation of the elevator is carried out by a gear motor, which is mounted on the upper drive drum.Coarse air purification system:

Instead of the outdated cyclone system, a precipitation ladder is used in the shot blasting chamber: air, together with shot and dust particles, enters the ladder, inside which a movable plate is provided. Large particles hitting the plate return to the system, and the dust enters the filter. By adjusting the height of the plate, you can change the size of the particles returned to the system. The precipitation ladder reduces the shot abrasive consumption by 10% and significantly increases the service life of filters.Cartridge-type dust removal system:

The filter unit "F - 8000" is designed to capture dry metal dust formed as a result of shot blasting. They are designed to work in heavy industrial conditions, to capture a large volume of dust during continuous processing. The dust in the filter unit "F8000" is captured by special cartridges with a dust cleaning and accumulation system, while they are simple and unpretentious to maintain. The unit is equipped with 8 cartridges. The cleaning system removes dust from the surface of the cartridges by accumulating it in a special dust container.

Control cabinet:

The automated control system of the shot blaster includes equipment from leading European and domestic manufacturers. The system ensures efficient and safe operation of the equipment throughout the entire period of operation. The automated control system of the shot blaster is built on the2 basis of a panel controller from B & R (in terms of quality parameters, it is not inferior to Siemens). It is installed on the local control panel of the shot blaster and is designed to implement algorithms for controlling equipment in manual and automatic mode, and also displays information about the condition of the equipment."

Your message has been sent successfully.